Mobility Hubs: Difference between revisions

No edit summary |

No edit summary |

||

| Line 15: | Line 15: | ||

people stop for food and coffee, to pick up and drop off packages, and to do some local shopping on their way to and from work. Attachment A of this | people stop for food and coffee, to pick up and drop off packages, and to do some local shopping on their way to and from work. Attachment A of this | ||

document offers an “EV-Ready Transit Hubs White Paper” exploring this topic in more detail. | document offers an “EV-Ready Transit Hubs White Paper” exploring this topic in more detail. | ||

=Electric Vehicle Charging Infrastructure= | |||

We plan to work with Forth Mobility on demonstration projects to advance electric, smart and shared transportation. We plan to work with Portland General | |||

Electric Company (PGE) and their efforts to accelerate transportation electrification. | |||

=Maintenance and System Operation= | |||

Urban Speed Electric Vehicles like Mobility Cubed’s World Bus are constructed with less than 300 major parts, compared to over 2,500 parts for a typical | |||

gasoline engine vehicle. In addition, these vehicle’s assembly techniques are significantly less complicated than typical gasoline engine vehicles. | |||

The small bill of materials coupled with streamlined assembly processes enable Mobility Cubed to deploy relatively small (5,000 unit) volume runs of | |||

vehicles. The vehicles can be assembled and maintained at facilities near their operation, thereby providing local jobs, supporting the local economy, | |||

reducing shipping and logistics costs. | |||

[[File:Transit Hubs.pdf|400px|EV-Ready Transit Hubs White Paper]] | [[File:Transit Hubs.pdf|400px|EV-Ready Transit Hubs White Paper]] | ||

Revision as of 23:17, December 5, 2021

| Transportation | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||||||||||||||||||

| Sectors | Utility Transportation | |||||||||||||||||||||||||||||||||||

| Contact | Wilfred Pinfold | |||||||||||||||||||||||||||||||||||

| Topics |

| |||||||||||||||||||||||||||||||||||

Activities

Press

| ||||||||||||||||||||||||||||||||||||

- Authors

[[File:|x100px|link=Tim Smith]]

[[File:|x100px|link=Tim Smith]]

[[File:|x100px|link=Cory Marshall]]

[[File:|x100px|link=Cory Marshall]]

{{{summary}}}

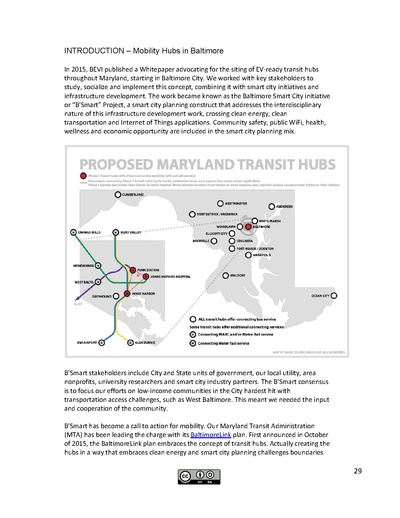

Any transit stop can be turned into a Mobility hub where the first and last mile vehicles are serviced, charged and stored when not in service. At these hubs passenger experience can be improved with digital information signs that respond to real-time conditions, improved lighting, improved pedestrian safety, bike racks, improved safety including CCTV cameras, and much more.

Using technology to increase safety and security at transportation hubs improves ridership and reduces cost. Transit hubs can become business hubs where people stop for food and coffee, to pick up and drop off packages, and to do some local shopping on their way to and from work. Attachment A of this document offers an “EV-Ready Transit Hubs White Paper” exploring this topic in more detail.

Electric Vehicle Charging Infrastructure

We plan to work with Forth Mobility on demonstration projects to advance electric, smart and shared transportation. We plan to work with Portland General Electric Company (PGE) and their efforts to accelerate transportation electrification.

Maintenance and System Operation

Urban Speed Electric Vehicles like Mobility Cubed’s World Bus are constructed with less than 300 major parts, compared to over 2,500 parts for a typical gasoline engine vehicle. In addition, these vehicle’s assembly techniques are significantly less complicated than typical gasoline engine vehicles. The small bill of materials coupled with streamlined assembly processes enable Mobility Cubed to deploy relatively small (5,000 unit) volume runs of vehicles. The vehicles can be assembled and maintained at facilities near their operation, thereby providing local jobs, supporting the local economy, reducing shipping and logistics costs.