Smart Buildings O&M

| Smart Buildings | |

|---|---|

| |

| Sectors | Smart Buildings |

| Contact | Jiri Skopek |

| Topics | |

- Authors

This section explores how the next generation of smart building operations, functionality and maintenance is utilizing the Internet of Things (IoT) to operate at full interconnectivity, functionality and efficiency.

Objective

Smart building, operations, functionality and maintenance capabilities cut energy consumption and CO2 emissions, reduce maintenance costs, improve performance and extend equipment lifetime. Various systems offer actionable insights, drive fewer complaints from occupants, decrease the need for unscheduled maintenance and reduce energy costs and carbon footprint. In time of pandemic or other extreme events, smart buildings may offer autonomous operation.

For many people, the idea of a SMART building creates and implies an image of a building with complex IoT applications that can only be understood, integrated and operated by a cadre of a highly trained facility, IT, and project management professionals. A similar apprehension existed with the first generation of buildings with BAS (Building Automation System)— i.e. an intelligent system of both hardware and software, connecting heating, venting and air conditioning system (HVAC), lighting, security, and other systems to communicate on a single platform. Most larger buildings today have a BAS system which provides significant energy saving and operational benefits for its owners and occupants.

An introduction of AI systems now expands the operational capabilities and even suggests the possibility of fully autonomously operated buildings, connecting with and responding to the signals from the utility grid or other systems in the city nearby.

Smart Building Operations

The difference between BAS and the smart, connected building operations

The difference between BAS and smart building operations is the ability to gather data, analyze and diagnose problems from multiple data input sources. Smart operations also involve interoperability and sharing data from multiple systems within building(s). Building automation systems (BAS) help facility owners conserve energy and optimize performance with controls that allow for examples like scheduling equipment, occupancy schedules and maintaining occupied/unoccupied set-points. Smart building operations are the next step in this evolution and represent a facility's ability to gather the data and change operational outcomes accordingly. The key is data acquisition, analytics, diagnostics and interoperability.

The transition to smart operations does not have to occur all at once but can be gradual and phased. For owners with a robust, and at some levels integrated BAS in their facilities today, transitioning to a smart building environment will be easier to accomplish.

The very first step is to install a communications network which building systems, equipment and devices can share data and interoperate quickly and efficiiently. Adding smart meters is often the first system to be connected to this network. This can provide near-real-time energy usage data showing energy consumption, and in some cases, at what cost. This on its own has the advantage of improving a building operator's insights to save energy, reducing the carbon footprint, improving the longevity of equipment and reducing costs. Smart meters offer utility monitoring opportunities on a more granular basis toward the conservation of our natural resources. The systematic tracking and optimization of building energy consumption with visual dashboards can also help not only to change the behavior of building occupants but also connect and make the building responsive to the price and demand signals from the grid as connected buildings. Blueprint Chapter 6 – Interfacing with City Services and Utilities provides further explanation.

The building operation KPI’s [Key Performance Indicators]

How do we evaluate the effectiveness of the building operations? Every building and the function of that building may have different performance metrics. Some standard KPI’s for the building operation may be:

- Lower energy performance gap: building operation presents several inefficiencies compared to project conditions that lead to an energy performance gap. This gap can be reduced by monitoring systems.

- Lower maintenance and replacement costs: smart-ready services reduce maintenance and replacement costs since they permit to prevent or detect faults and failures.

- Higher Occupant Satisfaction: Temperature, Humidity, Lighting, Indoor Air Quality and controllability often lead to high occupant satisfaction.

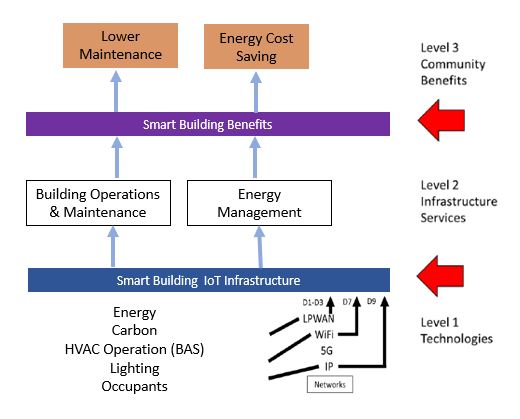

Using the holistic H-KPI framework1, provides a more comprehensive view, enables aggregation and normalization of smart building indicators, and allows better quantification and comparison of operations in different types of buildings, The H-KPIs use three levels: Level 1- technology, Level 2- infrastructure and level 3 – benefits.

The interactions across the three levels of analysis is a central component of the H-KPI methodology. For example, sensors deployed at Level 1 inform the building management infrastructures at Level 2. The benefits of deploying the smart controls are then manifested at level 3.

Figure 1: Operational and Energy Savings

Level 1 Technology

The first step is to install sensors to monitor building performance in real-time. Sensors provide data to a one or more processing units that uses that information to drive heating and cooling equipment as well as actuators, dampers, fans and other components to control a building's operation. They are capable of collecting environmental and operational data of buildings and reacting to the collected information in real time. They are the front end of smart building systems.

From a data standpoint, a commercial building is a complex business with diverse needs. The right combination of sensors in an integrated network is worth much more than the sum of its parts, with significant value for predictive maintenance, operational efficiency, downtime reduction, environment stabilization, and occupant comfort1. The following are the type of sensors found in smart buildings:

AHUs, chillers, and boilers all need pressure sensors to monitor pressure in ducts, condensers, and evaporators, and water supplies. High or low pressure readings are an invaluable predictor of leaks, pump failures, locked rotors, clogs, and other mechanical failures. They’ll provide proof of flow and can be used as a control point for things like fan speeds or air flow through duct work. You’ll also be able to monitor building zone pressure to regulate the inflow of outside air.

Many facilities have precise environmental humidity requirements — laboratories, libraries, manufacturing plants, et cetera — due to the materials or processes housed within them. Even in office and residential buildings, however, humidity regulation is a critical component of occupant comfort. Humidity sensors within air handling units help you determine how much outside air you need to introduce into the building and keep you timely in your response when RH is exiting the desired range.

Few sensors see more widespread use in HVAC than temperature sensors, which play crucial roles in virtually all units. Your temperature sensors will monitor duct temperatures, chilled and heated water loops, inside and outside air temperatures, and more. They also provide input for functions such as fan or valve control and flow regulation.

These are essential for tracking the run status of all fan and pump motors. A current sensor provides proof of function and eliminates the need to manually check each unit to see if it’s running. If current is flowing, the unit is working.

The best way to reduce costs on constant conditioning of outside air is to track CO2 for Demand Control Ventilation (DCV) and either recirculate inside air or introduce fresh air, as needed.

A power meter in a chiller or boiler helps with the efficient management of load shedding agreements and detection of mechanical problems (when, for example, power usage is excessive).

Water flow (both return and supply lines) must be monitored in boilers, chillers, or cooling towers to provide proof of flow and measure usage. BTU meters are a version that combine the functions of flow meters and temperature sensors to trend energy usage and detect inefficiencies (which may result from clogs, excessive ice, humidity changes, and other malfunctions).

These devices track amperage (current) that passes through a conductor. The format of the switch will vary, depending on the application. They’re useful in monitoring the status and run times of circuits, motors, and equipment while also detecting mechanical failures.

A relay can provide a layer of protection for mechanical equipment that may overload under excessive currents. A load-switching relay can easily handle resistive currents for lighting fixtures (e.g. incandescent, LED, fluorescent), and capacitive currents (such as power supplies and loudspeakers). Inductive loads, as with fans, transformers, and electromotors, require careful attention to maximum loads to prevent damage to the relay.

A transducer modifies an electrical input to a different kind of signal either passively or actively. These are used for monitoring load trending data and the controls and status of the equipment (such as a fan or pump) receiving the altered signal.

IAQ compliance requires careful monitoring of the indoor climate with sensors that track RH, CO2, temperature, and VOC outputs. It’s also critical to track these things for the general comfort and safety of occupants and to protect sensitive materials or equipment. Such units can be wall or ceiling-mounted, and fitted to be controlled by hand or remotely via the BMS or even a wireless application. While it is possible to install individual sensor types for each aspect of IAQ, the best and most cost-effective approach would be to install a network of all-in-one style sensors with the capability to monitor every aspect (or as many as possible) from a single device in each location.

When it comes down to it, building management is about keeping a building functional and cost-efficient for the people and processes housed within. This is most achievable with an accurate data model on space usage — where, how long, and in what numbers people are residing in the building — to guide the setpoints and schedules in your system. Some systems can be turned down or off, even during times the building is in use, if certain areas are less active or perhaps not active at all. Data from occupancy sensors will guide planned maintenance outages, field service of equipment, energy management for peak hours or off hours, and more.

For example, temperature sensors allow you to measure and monitor ambient, or surface conditions in or around the building, in real-time. This allows you to maintain optimum conditions and improve efficiency. Desk occupancy sensors detect and monitor the presence of people, in real-time.

Where (and Why) Should Sensors be used?

Sensors and meters need to be integrated throughout the building, from individual flow meters within the valves of a boiler’s hot water loop to a simple wall thermostat in the lobby. Each sensor acts like a nerve that connects HVAC, power, lighting, and other systems to the BMS for a complete picture of unit health and performance. It’s critical that sensors are installed within the following units and systems for an optimal set of control points and insights.

The AHU will use an array of pressure, humidity, temperature, current, and CO2 sensors to keep operations efficient and help you optimize setpoint automations and strategic cycle scheduling. Pressure sensors keep track of filter status, whereas RH, CO2, and temperature sensors should be positioned periodically in all ducts. A current sensor monitors each fan motor.

Water Cooled Chillers: The chilled water loop and condenser water loop will need temperature sensors to help you better control the valve that determines circulation speeds. Return and supply lines use flow meters to provide proof of function and gauge pressure sensors to enable the BMS to calculate differential pressure between supply and return. A current sensor is needed for all pump motors to detect on/off status, locked rotors, and functionality.

Use a flow meter on both the supply and the sewer drain to reduce your costs. The meter helps you detect how much water went down the drain by showing the difference between the volume of water initially supplied and the water discharged into the sewer. As much as 50-60% could be lost to evaporation. Proving this will save on utility charges that assume all water supplied was also sent into the sewer system. Immersion temperature sensors are a useful control input for fan rotation, and as with other units, current sensors should track all pumps and fans to ensure they’re working.

Temperature sensors provide the needed input to control dampers, fan speeds, or power to suit the demands of the space. VAV boxes with heating and cooling coils will also use temperature sensors to control those points. A current sensor monitors the fan motor (and thus the fan status).

The boiler requires a complex network of sensors to track power, pressure, current, temperature, and flow. The power meter assists in regulating load shedding processes as well as detecting issues in the boiler pump motor. Current sensors also provide proof of function for the pump motor. Gauge pressure sensors monitor the supply and return lines for total pressure (and allow for calculation of differential pressure). Temperature sensors track the heated water loop to help you determine pump speed and control the valve for water recirculation with efficiency. BTU flow meters are a valuable input for trending boiler efficiency and measuring the total energy it consumes. Overconsumption can indicate compressor cycling issues, clogs, or malfunctioning pumps.

An optimal energy bill depends upon efficient management of your energy consumption. Modern power and current monitoring systems must provide more than a whole-building view. Individual breakouts of performance and trends at each circuit enable you to pinpoint energy consumption, detect inefficiencies or problems, and predict electrical or equipment-based maintenance needs. It’s best to meter as many lighting circuits, fans, motors, pumps, and equipment power supplies as is feasible. An ideal meter can accurately monitor 50, 100, or potentially even more circuits — you won’t need a matching number of meters to make individual monitoring possible.

Wall-mounted and ceiling-mounted IAQ and occupancy sensors can be easily fitted for every room or hall that will be occupied or contain climate-sensitive materials or equipment. Keep precise track of the humidity, temperature, and CO2/VOC levels in these areas to detect potential blockages or failures in the ventilation system and to respond quickly to increased needs in times of high occupancy. In many applications, these sensors will also be necessary to help you maintain compliance with codes for the space.

Additional devices and systems may include door access sensors, video cameras, vertical transportation, office and desk reservation systems, parking sensors and many more. More and more devices and systems are creating data and becoming interoperable and can be connected to a smart building system. The key is to evaluate these with your KPIs; if there is a benefit to interoperability for these devices then connection can be justified.

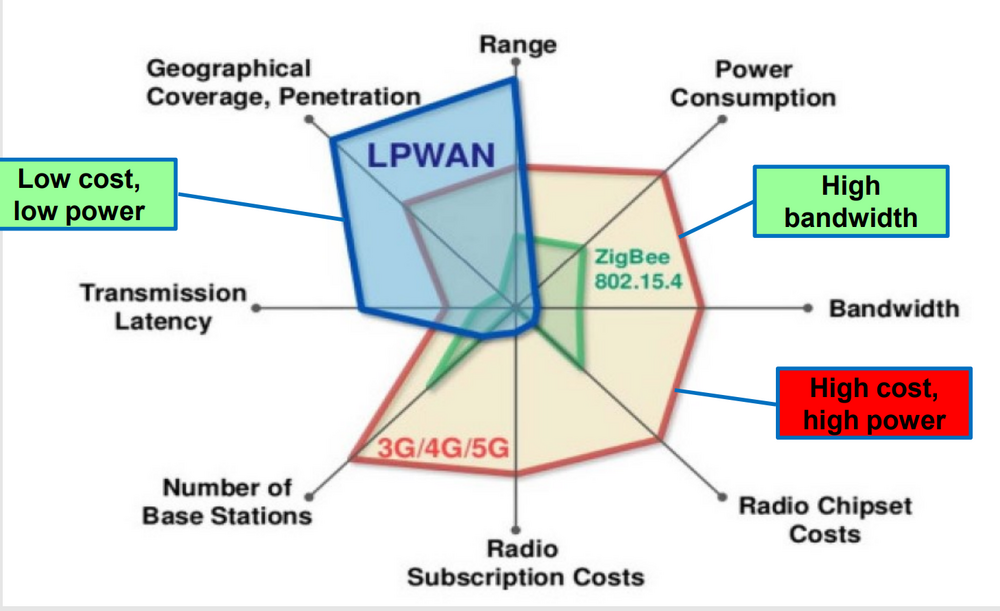

IoT connectivity

Connectivity can be through a physical cable connection or through a wireless network. Wireless network conductivity is becoming much more widespread. The first generation of wireless was often considered unsecured but the newer generation of wireless networks provides greater security than the original versions. The options for wireless and the ease of connection has created great opportunity to connect multiple devices. The amount of available sensors, demands many wireless technologies and options. The existing wireless IoT connectivity technologies include diverse types of connectivity technologies, such as LPWAN, 5G, Bluetooth, WIFI, IP with different frequency ranges, specifications and performance characteristics. The key here is that each network should be secured and devices connected using a non-standard code or password.

Level 2 Infrastructure Services

The current technology, otherwise known as Big Data Analytics (BDA) and Fault Detection and Diagnosis (FDD), typically consists of a locally stored or cloud-based analytical engine that receives and analyzes building data and communicates the diagnostic information, typically through a series of work orders. This BDA or FDD software can be installed in the controller of the equipment (often referred to as the edge), within the main building controllers or in a remote (cloud) server. Edge installations provide quicker decision results and actions while cloud applications can provide greater global evaluations and analytics. These are the terms used to describe the process of tracking and analyzing building performance and energy efficiency continuously and in real-time of heating, ventilation and air conditioning (HVAC) systems, lighting (for example, daylight saving and shutting off lights in unoccupied zones), indoor air quality (IAQ) monitoring, smart elevators and so forth to alert the building operators of faults or inefficiencies within the building systems. To avoid being overwhelmed by too many notifications, algorithms can be put in place to prioritize and indicate the work orders that are a priority, and which will have the greatest positive impact on building performance.

Fault detection and diagnosis enable timely and targeted interventions in cases of faulty or underperforming building equipment. This equates to continuous commissioning. Smart building sensors are not limited only to energy usage problems but can also address other systems, for example, identifying water leaks, equipment which may be near faulting or waste bins that need emptying. In the longer term, BAS will soon become less important, as more and more equipment will be manufactured with integrated controls and sensors that can be wired or wirelessly connected to the network and driven by a smart building software platform — like 'plug and play. As more and more data and the skill sets to collect them increase, the analytics will mature and reveal patterns and feedback mechanisms that will enable the development of data-driven knowledge and operations. Like self-driving cars, this may lead to self-operating buildings, where the analytic and diagnostic capabilities of smart buildings will allow for remote operation of the buildings. With the information relayed via the cloud about the operation of the building's heating, ventilation, air conditioning (HVAC) and lighting control systems, the building operator will be able to monitor and control the building operations remotely for energy consumption. This is also valuable in times of emergency, such as pandemics.

The difference between remote, cloud-based and on-premises, edge computing infrastructure1

The AI now being deployed started life as a cloud computing technology. The machine learning algorithms under the hood of these systems require significant computing power, both to train the algorithms and get them to deliver insights – a process called inferencing. Until recently, on-premises infrastructure rarely had the resources to effectively do those things and, as such, building operators had to run their AI applications out of data centers.

Yet, running smart building applications out of remote data centers has its own limitations. Connectivity, bandwidth costs, security and latency – the time it takes to send data to the cloud and back – can impact a system’s efficacy. If a machine, or an entire building automation system, is going to fail, the alarm and automated response need to be as immediate as possible.

That issue has largely been mitigated by a new generation of edge computing technology: infrastructure installed in facilities with the processing power demanded by these compute-intensive workloads.

There are now many companies, like FogHorn, Hank, Brain Box, to name a few, that use Edge AI technology that creates new possibilities to digitally transform building operations. This includes advanced technology (known as Edgification) to optimize AI models to run efficiently on low-cost edge computing devices. By closing the on-premises capability gap, edge devices provide an architectural component important for achieving the goal of running a building as efficiently and effectively as possible.

Choosing between the cloud and Edge AI

With the availability of Edge AI, building managers inevitably face the question of whether to deploy AI on-premises or in the cloud. For those facing this question, there are some simple rules of thumb to consider.

Edge AI is best when:

Actions need to be executed in real-time, or close to it. Smart automation systems that detect operational problems and automatically alert or respond to them tend to work best when the latency is minimized as much as possible.

Local control of a system is required. Turning off a machine or adjusting a control system from the cloud often runs into security and latency challenges. There are limitations to data transit and storage costs. Take for example, a video monitoring system in which high-fidelity images from multiple cameras are analyzed by a computer vision AI model, a popular AI application. Sending to and storing all that data in the cloud can quickly become cost prohibitive.

The cloud may be better when:

Completing rigorous data analysis. Often building managers want a deeper understanding of how they’re operating based on AI analytics, or to run simulation exercises on a ‘digital twin’ version of their facilities. That kind of data analysis typically doesn’t need to happen in real time, so it’s best executed in the cloud, where the managers can harness at any scale the most powerful hardware and software tools for the job.

A combination of both may be best when the enterprise is running multiple buildings and correlating information between them. The cloud allows for a centralized data clearinghouse and command center. As a practical matter, a hybrid approach is typically employed where some initial processing in the individual buildings happens through Edge AI and then cloud AI is run on the aggregated data from multiple buildings, possibly combining other data sources.

A digital twin manifestation of the building would further extend the building operators' capability to access all operational data remotely.

A combination of building automation and AI would further support a self-operating building that requires little to no human intervention. There are other advantages to using AI apart from a remote operation. AI would also be able to most efficiently maintain balanced thermal equilibrium in a building under any circumstances while at the same time ensuring occupant comfort, saving money, and reducing the carbon footprint.

There are still barriers to smart buildings. They include a general mistrust of artificial intelligence and the significantly higher cost of deploying AI-powered platforms. While there is some progress, there is still some work to be done to integrate protocols for various types of equipment used in smart buildings. Machine learning algorithms and more advanced statistical algorithms are also being developed to perform increasingly complex learning processes. Notwithstanding, the challenges, the use of artificial intelligence in building management is a strong trend, and the adoption of artificially artificial AI-powered BMS platforms is projected to increase, especially in new design and construction.

Due to the widespread of cloud-based applications and smart building technologies, which are now linking cyber and physical infrastructure, cybersecurity controls are increasingly essential to protect occupants, building infrastructure, and smart building functions against cyberattacks. Blueprint Chapter 4 – Cybersecurity Considerations explores this issue further.

From preventative maintenance to predictive maintenance

The same integrated sensors that provide performance data — historical and in real-time — support a more predictive maintenance program by detecting failures before they occur. For example, the data may show that a fan coil unit has been running at 100% output for more than one month, at a higher measured sensor temperature and therefore requires maintenance activities earlier than planned.

A review of the work orders that have been issued for each piece of equipment will identify the equipment that may soon need replacing. This proactive monitoring of devices and endpoints has a high return on investment for labour and product replacement. This can then be included in the capital plan. Another intelligence can be provided to the facility Inventory systems such that if one of the parts scanned out of inventory is taken for use, a replacement part is automatically ordered. This can create a recommended spare parts list to be kept on hand.

Level 3 Community Benefits

Incremental investments in smart building systems and their operation and management offer a good return on investment. Given that the main role of building managers is to save money and gain and retain occupants, it is therefore not surprising that the main focus has been on energy savings — energy being a key controllable item — with energy management and information systems for energy monitoring, measurement and verification (M&V), demand management and HVAC optimization.

Admittedly, smart building technology requires a certain level of capital expenditure for installation, migration and interface with often dissimilar existing building automation or control systems. However, the cost of upgrades pales in comparison to the operational savings. As building components and installations become cheaper, and smart buildings need less on-site, hands-on operations, owners, occupiers, and investors in real estate are starting to realize that these systems are becoming essential to remain competitive in the marketplace.

For example, a large, global financial services firm installed low-cost wireless sensors and controllers on its branch facilities, which numbered in the thousands, to enable remote monitoring and control of HVAC and lighting systems. Energy savings averaged 13 percent annually, while savings from fewer maintenance technician visits added another 5 percent in overall operating expense savings2.

In the short term, the business case for smart buildings is bolstered by the energy-savings potential of strategically chosen smart building features, and accurate service history and asset condition, which enables maintenance activities to be more efficiently scheduled, and accurate maintenance logs to ensure that operators only pay for work that was completed.

Operational savings appear to offer even greater savings with fault detection, predictive equipment analysis, predictive cleaning and so forth. Since every piece of equipment can be monitored and dealt with based on work orders, this provides a record of how many work orders have been issued on each piece of equipment. These records help to identify which equipment may need to be replaced as part of the capital plan. All of this dramatically reduces the time and cost of operations and maintenance with efficiency gains of fifty to seventy percent. For example, Microsoft is already using AI to improve operations on its eighty-eight-acre campus. Microsoft now also operates one hundred percent carbon neutral. Because buildings emit forty percent of carbon, these are the kinds of savings that are needed to fight the climate emergency and help cities and states meet their goals, such as in NYC NYSERDA's Retrofit NY or California's Low-Carbon Buildings Bill AB 3232.

Thanks to extraordinary payback periods of one to two years, it is no wonder that owners and investors are installing smart systems and engaging smart building management services to optimize the performance of their portfolios and maintain a competitive edge leasing faster because of lower operating expenses than their peers and commanding a better price on sale.

Smart buildings also contribute to Return on Investment (ROI) that, includes jobs, tax revenue, and higher quality of life. So smart buildings can achieve better energy efficiency and reduce operating costs, they can make the building operate better increasing the building investment and the occupants in the building can be more productive allowing the business housed in the building to make more money. This can be explained in greater detail in, Blueprint Chapter 1 – Value, Benefit and ROI Considerations provides further explanation.

Incremental capital expenditure that offers a rapid return on investment (ROI)

Organizations that want to make their portfolio smart, do not have to do it all at once. A smart building expert can review the portfolio to identify the best ROI opportunities for example, from adding smart sensors and controls to existing equipment. As wireless technologies avoid the need for costly hardwiring and renovation, relatively small and incremental upgrades can give owners control of their investment in smart systems. Impressive savings can be generated in the short term as these systems reflag and reduce inefficiencies.

Here is one example. Some buildings use cool outside air or 'free-cooling' to reduce the amount of air conditioning that needs to run. If the dampers that allow the cool air to enter become inadvertently stuck in a closed position, then the free cooling may not be working at all without anyone being aware of it. Without the free cooling, the air conditioning may be using far more energy than needed, even though the occupants may not feel the difference. This situation could go undetected for months. A smart building management system would detect this in real-time and send an alert to fix the problem.

Smart building management services can also be scaled up or down according to how many facilities data analysis and reporting the owners and investors want, with fees that are generally priced based on the number of wireless sensors and data points tracked.

None of this removes the role of property or facility managers from the equation. The advantage of allowing machines to monitor machines 24 hours a day is that it releases building operators to address more pressing tasks. This is especially valuable, where many small buildings are being maintained by only a handful of facility managers.

New Developments in Operations and Maintenance

Digital Twin

Looking to the future, many buildings and their systems will be replicated digitally via a so-called "digital twin", either as detailed graphic representations or in the form of data, so that whatever occurs in the building will be visible and controllable virtually and in real-time.

Digital Twin, in the context of the built environment, refers to a digital replica of physical assets (physical twin), places, processes, systems, and devices. This digital data can be used for a variety of purposes, including building design, space management, operation and maintenance, the gathering, analysis and diagnostics of property data, creation of new services, and more. The digital representation provides both the elements and dynamics of the building in its entity, including systems and devices, as well as operating throughout its lifecycle.

While a digital twin consists of an exact representation of a building in the format of digital data, the easiest way to comprehend the data is by using a 3D model. This dual representation can cause confusion with BIM. BIM data enables collaboration and visualization during design and construction, but not during operations and maintenance. Thus, to create a digital twin for new construction it is possible to start with a BIM model based on the construction information (plans and data for the building). A digital twin represents how people interact with the built environment. It uses automated sensor technology for information updates to reflect real-time changes. For existing buildings, the digital twin can be created with real-time sensor data from the building management system, data from HVAC systems, lighting, fire, security, and other environmental sensors, as well as data about the assets of the building and the people who use it, such as tenants, occupants, building staff, visitors, and other roles. This creates a rich virtual information model of an entire building, which allows for detailed and accurate analytics of maintenance data and asset usage optimization based on financial impacts and costs. This helps to operate buildings more efficiently by helping predict and avoid unexpected costs, identifying system inefficiencies and better estimating when replacement parts are needed. Running simulations on a digital twin reduces risks and helps system engineers make better business case for changes to the system.

Facilities Informatics and applied technology

Facilities informatics (FI) is the intersection of facilities, IM/IT, and management practices to improve operations, based on facilities-related data, information, and knowledge3.

Facilities informatics has its origin in the medical field to organize and understand patient data – individually and in the context of population trends, for example, when a cluster of patients covered by different physicians may be experiencing similar conditions.

At the level of the individual patient, it keeps track of medical information electronically; informs physicians about how a patient's condition, local or remotely, is changing over time; provides insights during the diagnostic phase and the care process, including information on potential treatments; automates pharmacy requests, and facilitates effective and constant communication between the patient and physician.

For hospital managers, this data offers a better understanding of the workflow of their hospital so that they can plan for predictable, not-readily noticed patterns in patients, and react more quickly to situations that are trending out of normal bounds.

A similar approach is now being developed for buildings and facilities management. The goal of facilities informatics is to develop wisdom from data to inform decision-making processes related to energy, maintenance, and capital programs. Some examples of facilities informatics applications include the design, development, implementation, maintenance, and evaluation of:

- hardware options

- communication protocols for the secure transmission of facilities data

- electronic facilities record systems (regionally, provincially, territorially, or nationally)

- evidence-based decision support systems

- classification systems using standardized terminology and coding

- work management systems

- facilities monitoring systems (e.g., computer-controlled BAS/EMS systems)

- digital imaging and image processing systems

- geospatial systems

- telework and mobile technologies to facilitate and support remote diagnosis and treatment

- Internet technology for engaging customers

- methodologies and applications for data analysis, management, and mining

- facilities information data warehouses and reporting systems

- business, financial, support, and logistics systems

Facilities informatics can be viewed as a parallel to Enterprise Data Management (EDM), which is starting to be used by many organizations to integrate, govern, secure, and disseminate data from multiple data streams, including data that is being safely transferred among partners, subsidiaries, applications, and/or processes. Similarly, building data, for example, from sensors monitoring energy and environmental conditions, are increasingly becoming part of this process.

Channeling buildings and facilities data through the same data processing and storage as the organization data may cause conflicts between the organization's information technology (IT) and operation technology (OT) departments. The building data are being generally viewed in the IT world as low-grade data susceptible to hacking and the threat to cybersecurity. To progress and overcome such perception increasingly requires IT/OT personnel to work together.

Reduction of peak demand and increased resiliency

Peak demand is a period in which electrical power is needed for a sustained period at a significantly higher than average supply level. This often causes power "blackouts or brownouts”. Fortunately, it only occurs a few times a year, usually on the hottest days or coldest days of the year, depending on the geography. However, with the increasing frequency of weather events due to climate change, such events are becoming more frequent. Traditional peak demand reduction techniques rely on cutting or reducing the use of certain building equipment such as elevators or A/C. Many utilities charge higher rates during "peak" times (either is demand charges [kW] or usage charges [kWh]). Connecting your smart meters to the smart building system can allow the building to help manage these complex rate schedules and "shed" load automatically during peak charge periods. Smart buildings may extend peak load reduction capabilities by offering the possibility to limit the need to invest in additional capacity to supply peak demand while improving the use and efficiency of existing resources. Blueprint Chapter 6 – Interfacing with City Services and Utilities further addresses how consumers can reduce or shift electrical usage during peak periods.

The integration of renewable and distributed energy resources (DER) in buildings that are 'grid partners' with utilities increases resiliency. For example, the integration of a microgrid consisting of photovoltaic modules, battery banks, and plug-in electric vehicles (PEVs) can reduce the peak load of the building as well as satisfy the PEVs load. The control strategy offers operational flexibility and the ability to take advantage of off-peak energy rates. Solar power can be maximized during the day and the batteries can be managed to be charged during low utility cost periods and dis-charged during high utility cost periods. When the main utility power fails, these DER can be used to extend the normal operation of the building until utility power can be restored. This can be achieved through exploiting power generated onsite, the local energy storage system, and the operational flexibilities of the PEVs via the vehicle-to-building alternative4.

Building interaction with the grid.

While climate change is losing its no.1. priority to the pandemic, both the pandemic and the climate crisis are problems of exponential growth against a limited capacity to cope. In the case of the coronavirus, the danger is the number of infected people overwhelming healthcare systems; with climate change, it is that emissions growth will overwhelm our ability to manage consequences such as droughts, floods, wildfires, and other extreme events. The current brief reduction in emissions due to coronavirus will not stop other catastrophic events which are already in motion. We need to build resiliency on all fronts. One such measure is a smart grid and transactive energy, where buildings will be the heart of the future grid.

Smart Grid is an electricity supply network that uses digital communications technology to detect and react to local changes in production and usage. Changes in a Distributed Energy Resources (DER) network may be caused by the uneven generation of renewables (wind and solar) as well as changes in usage by energy consumers. Operating the smart grid needs, both economic and control mechanisms to balance an electric power system. Such a mechanism is transactive energy.

The benefits associated with the Smart Grid include more efficient transmission of electricity and faster restoration of electricity after power disturbances as well as reduced operations and management costs for utilities and, ultimately, lower power costs for consumers. Combined with renewable power and storage, it also provides great resiliency, which in times of pandemic or other catastrophic events increases the grid coping capacity. The capability to respond to the changing condition, "talking to the grid," requires a smart platform solution capable of supporting the management of a wide range of applications, including heating, ventilation, and air-conditioning systems; electric vehicles; and distributed-energy and whole-building loads. Platforms such as VOLTRON5 are rapidly being developed and tested. They will be capable of responding to occupants' needs, producing and storing energy, and communicating with the utility, grid and other buildings.

Smart grids have the potential to boost resiliency and catalyze the efficient and sustainable use of electricity. Real-time access to supply and demand transactive energy platforms, enabled by smart grids, could deliver a value of $632 billion to society, higher than any other individual digital initiative.

Low voltage, Power over Ethernet (PoE) and DC microgrids

One concern that is now emerging is that digital technologies, such as those used by occupants (particularly streaming) are warming up the planet. These are currently responsible for 4% of greenhouse gas (GHG) emissions and are expected to double by 2025 to reach 8%, which is equivalent to the current share of car emissions. To counteract this trend is therefore important to look at other ways to decrease the energy consumption of buildings.

Direct Current (DC) microgrids and Power over Ethernet (POE) may offer alternate solutions. Solar panels produce DC current, which is what computers, LED lighting and electric cars use. The advantage of a DC microgrid is that it can supply renewable energy to supply these end uses during the time it is consumed. Many innovative DC-run building components are now coming onto the market. For example, smart DC motors are being installed to replace inefficient and unintelligent AC induction motors on HVAC systems. These are more efficient, provide better control and are more durable than variable-speed-driven motors, which throttle back power by inducing a current in the motor, but which produce heat and other side effects from the electrical resistance. An example of a PoE building is the Marriot Hotel in Fort Worth, Texas. DC microgrids can supply not only buildings but entire cities. The issue with DC is that it cannot be transmitted long distances.

Summary

With buildings consuming 40% of energy, smart technology will contribute to much-needed operational efficiency, leading to significant carbon reduction and a good return on investment due to enhanced occupant retention and value. Smart buildings that integrate renewable energy will also become the heart of the future grid, as noted in the Blueprint Chapter 6 – Interfacing with City Services and Utilities. However, the integration with cloud-based services and application continues to present security threats which can be addressed as described in Blueprint Chapter 4 – Cybersecurity Considerations.

References

- ^ John Hatcher. "Cloud vs. Edge AI: What’s best for your facility?". https://smartbuildingsmagazine.com/features/cloud-vs-edge-ai-whats-best-for-your-facility, 2022, .

- ^ "The Changing Face of Smart Buildings: The Op-Ex Advantage".

, Jones Lang LaSalle, 2022, .

, Jones Lang LaSalle, 2022, . - ^ "APPA Facilities Informatics Maturity Matrix Technical Report".

, APPA, 2016, .

, APPA, 2016, . - ^ Hanane Dagdougui, Ahmed Ouammi, Louis A. Dessaint. "Peak Load Reduction in a Smart Building Integrating Microgrid and V2B-Based Demand Response Scheme". Institute of Electrical and Electronics Engineers (IEEE), 2019, Vol = 13, Issue = 3, pp. 3274-3282, DOI = 10.1109/jsyst.2018.2880864.

- ^ Cort, KA, Haack, JN, Katipamula, S, Nicholls, AK. "VOLTTRON™: Tech-to-Market Best-Practices Guide for Small- and Medium-Sized Commercial Buildings".

, Pacific Northwest National Laboratory (PNNL), 2016, Issue = PNNL-25405, .

, Pacific Northwest National Laboratory (PNNL), 2016, Issue = PNNL-25405, .